Construction process of standard industrial factory from planning to acceptance

In the field of industrial manufacturing, standard industrial factory is the core infrastructure supporting production activities. With the advancement of modern construction technology, steel structure plant has gradually become the mainstream choice due to its high efficiency, durability and environmental protection.

1. What is a standard industrial factory?

A standard industrial factory is a general industrial production building built according to unified planning, design and construction standards. Standard industrial plant is an industrial building built in a standardized process, which can adapt to the needs of multiple industries such as machinery manufacturing, electronic processing, warehousing and logistics. It is usually located in an industrial park and provides unified supporting facilities.

2. Advantages of standard industrial factory

Versatility and flexibility

- Standardized design can adapt to the production processes of different industries, such as machinery manufacturing, electronic processing, warehousing and logistics, etc., reducing the cost of enterprise transformation.

- Flexible spatial layout, can adjust parameters such as partition, floor height, load-bearing capacity according to needs.

Reduce enterprise costs

- Low construction cost: unified construction reduces land, material and labor costs, and enterprises do not need to expropriate land, design and construct by themselves.

- Low time cost: Ready-made factories can be quickly settled in, shortening the production cycle.

- Low operating cost: Centrally managed supporting facilities such as water, electricity, gas, and networks reduce corporate maintenance costs.

Complete supporting facilities

Usually equipped with infrastructure such as roads, parking lots, sewage treatment, and fire protection systems, some parks also provide employee dormitories, catering, logistics and other services.

Environmental protection and compliance

Standardized factory design meets environmental protection requirements, reduces pollution emissions, and reduces corporate environmental compliance risks.

High investment value

Standardized factories are easy to rent or transfer, and have stable investment returns, especially in areas with active industrial development.

3. Preliminary planning and demand analysis

Clear functional requirements

- According to the production needs of the enterprise (such as equipment layout, logistics flow line, storage space, etc.), determine the area, floor height, load-bearing capacity and special functional areas (such as dust-proof workshop, constant temperature warehouse) of the factory.

- Steel structure factory building can quickly meet diverse needs due to its flexible design adaptability.

Site selection and land approval

- Choose a location that conforms to the industrial land planning to ensure convenient transportation and complete infrastructure.

- Complete approval procedures such as land acquisition, environmental impact assessment report and construction permit.

4. Design and scheme formulation

Architectural scheme design

- A professional design team plans the factory floor plan, ventilation and lighting, fire escape, etc. in combination with production needs.

- The advantage of steel structure workshops lies in the large-span space design, which reduces the interference of columns and improves the space utilization rate.

Structural design deepening

- Steel structure company need to provide detailed structural calculations to ensure that load, earthquake resistance, wind resistance and other indicators meet national standards.

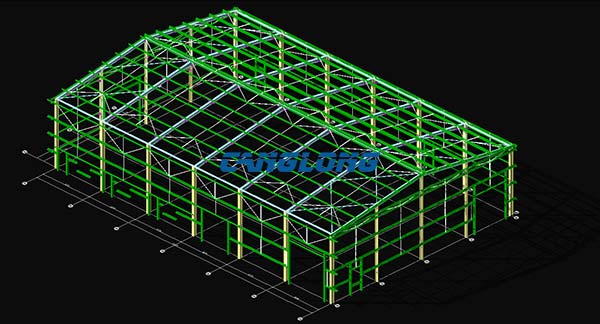

- Use BIM technology to optimize pipeline layout and avoid construction conflicts.

5. Construction preparation and material procurement

Choose a reliable steel structure company

- Give priority to steel structure companies with complete qualifications and rich cases to ensure material quality and construction professionalism.

- When signing the contract, specify the construction period, material specifications (such as H-shaped steel, sandwich panels) and acceptance standards.

Material procurement and processing

Steel structure components (steel beams, steel columns, purlins, etc.) are transported to the site after prefabrication in the factory to reduce on-site operation time.

6. Main structure construction stage

Foundation engineering

According to the geological survey report, foundation treatment (such as pile foundation or independent foundation) is carried out, and concrete cap is poured.

Steel structure installation

- Hoist steel columns and steel beams and weld them to form the main frame.

- Install roof panels and wall panels, with insulation and waterproof layers to improve the energy-saving performance of the factory.

Construction of auxiliary facilities

Pre-buried water and electricity pipelines, installed fire protection systems and hardened ground simultaneously.

7. Acceptance and delivery

Quality inspection

A third-party agency is commissioned to test the strength of steel structure welds, the thickness of fireproof coatings and the overall safety of the building.

Completion acceptance

- Check the design drawings and construction results, and handle the “Construction Project Completion Acceptance Registration Form”.

- Hand over the factory instructions and maintenance guide to ensure the smooth production of the enterprise.

8. Why choose a steel structure factory building?

- Short construction period: prefabricated production shortens the construction period by 30%-50%.

- Controllable costs: high material utilization rate and low later maintenance costs.

- Environmentally friendly and sustainable: steel can be recycled to reduce construction waste.

9. How to choose a professional steel structure company?

- Check the company’s qualifications (such as professional contracting qualifications for steel structure projects).

- Investigate past cases, especially similar industrial factory projects.

- Compare quotations and services to ensure cost-effectiveness and construction guarantees.

10. Conclusion

The construction of standard industrial factory is a systematic project involving planning, design, construction and acceptance. By choosing a professional steel structure company, enterprises can not only efficiently complete the construction of steel structure factory building, but also lay a solid foundation for long-term production operations. If you need to learn more about the factory building construction plan, please contact Canglong Group for customized solutions!